A 3D printer developed by Airbus under a European Space Agency contract will be the first to print metal components aboard the International Space Station.

Aboard the first Northrop Grumman Cygnus mission to be launched by a SpaceX Falcon 9 is a 180-kilogram 3D metal printer. The Cygnus spacecraft, which carried the name of late NASA astronaut Patricia Robertson, successfully docked with the orbiting laboratory’s Unity module on 1 February, approximately 18 hours after liftoff.

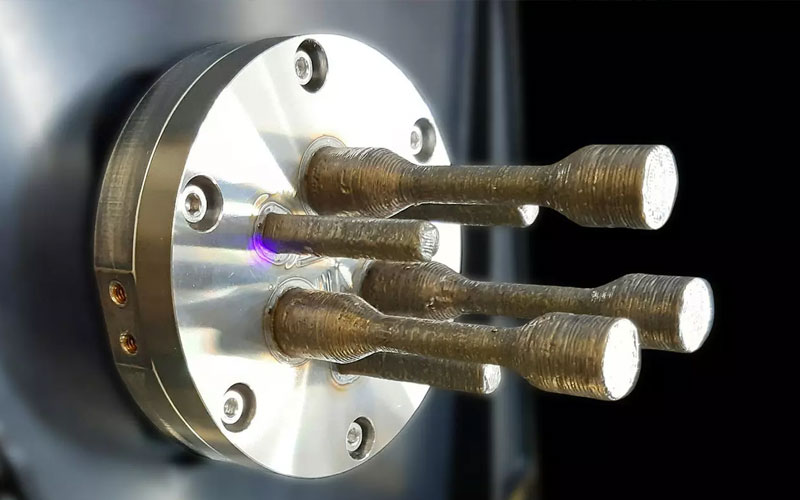

Housed inside a metal box, the printer, which appears to just be called 3D Metal, measures 80 centimetres wide, 70 centimetres high, and 40 centimetres deep. It will use stainless steel wire which, when heated to over 1,000 degrees centigrade, will be used to create printed parts roughly nine centimetres by five centimetres in size. A key element of the printer is an array of filters that capture fumes emitted during the printing process that would otherwise have contaminated the air inside the space station.

The printer was developed by an Airbus Defence and Space-led consortium that comprised AddUp, Cranfield University, and Highftech Engineering. While the programme was contracted and managed through ESA’s Directorate of Human and Robotic Exploration, development was funded by Airbus itself and a £546,000 grant from the UK Space Agency, which was awarded to the prime contractor through ESA.

The printer will be installed in the European Draw Rack Mark II, which is located in ESA’s Columbus module. The installation will be conducted by ESA astronaut Andreas Mogensen. Once operational, the printer will be controlled and monitored by operators on Earth.

A total of four sample parts will be printed aboard the International Space Station and then returned to Earth. It will take around 40 hours to print each part. The same four parts will also be printed on Earth using the printer’s engineering model. Researchers at ESA and the Danish Technical University will subject both sets of parts to mechanical strength and bending tests. A microstructural analysis will then be performed to determine how the parts made in space compare to those printed on Earth.