The European Space Agency and MT Aerospace have reached a significant milestone in the testing of a liquid oxygen tank that will be used aboard an upgraded Ariane 6 upper stage.

The Innovative Carbon ARiane Upper Stage (Icarus) initiative began in May 2019 with the aim of increasing the performance of the Ariane 6 launch vehicle. While the stage will not be utilized aboard the maiden flight or many of the vehicle’s initial flights, once it is introduced, it will allow Ariane 6 to carry even larger payloads to orbit.

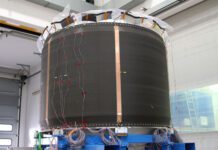

ArianeGroup was selected by ESA as the prime contractor to develop a demonstrator of the upgraded upper stage called Phoebus. MT Aerospace was selected as a subcontractor by the company to develop the carbon fiber-reinforced plastic liquid hydrogen and liquid oxygen tanks.

Development of the tanks began with a scaled demonstrator of the liquid oxygen tank that measured two metres in diameter. In late October, ESA announced that testing had begun on the stage, with room-temperature helium being used to ensure there weren’t any leaks. Liquid nitrogen was then used to ensure the tank could withstand the required cryogenic temperature and pressure. With the successful completion of this early testing, the tank could finally be tested with the liquid oxygen it was designed to hold.

While the initial testing was completed at MT Aerospace facilities in Augsburg, Germany, the stage was transported to a Rheinmetall military test site in Unterlüß. According to the ESA lead engineer on the project, Kate Underhill, the change of location was to ensure this leg of the testing could be conducted safely.

“When working with liquid oxygen, if things go wrong, they go wrong very quickly,” Underhill explained.

During testing at Unterlüß, the tank was filled with liquid oxygen to 95% of its capacity. After a cooling phase, the liquid oxygen levels were reduced to 50% of the tank’s capacity, at which point it was pressurized. The tests were completed successfully, demonstrating the tank’s compatibility with liquid oxygen.

“Phoebus is on a roll; the oxygen tank tests were a complete success, and the tank held it together perfectly – no fire, no explosion. I am a happy project manager,” said Underhill.

Testing of the subscale oxygen tank has, however, not been concluded just yet. The stage has been transported back to the MT Aerospace facility in Augsburg, where it will be fitted to a test rig that will subject the tank to the mechanical loads it will experience during flight.

While this final stage of testing is conducted, MT Aerospace will begin manufacturing a full-scale version of the tank that will have a diameter of nearly four metres. Additionally, testing of the hydrogen tank will begin in 2024 at the DLR propulsion testing site in Lampoldshausen.